ALIS on-site!

Keeping the maintenance status of your airport’s assets up to date works best when the digital registration happens as quickly as possible, which greatly depends on the technicians on-site. We have therefore developed the tools and the apps to suit the unique conditions we encounter on-site at the airport. From a few registrations to hundreds of them, ALIS has it all covered in order to keep your work and its registration quick and clear.

ALIS on-site!

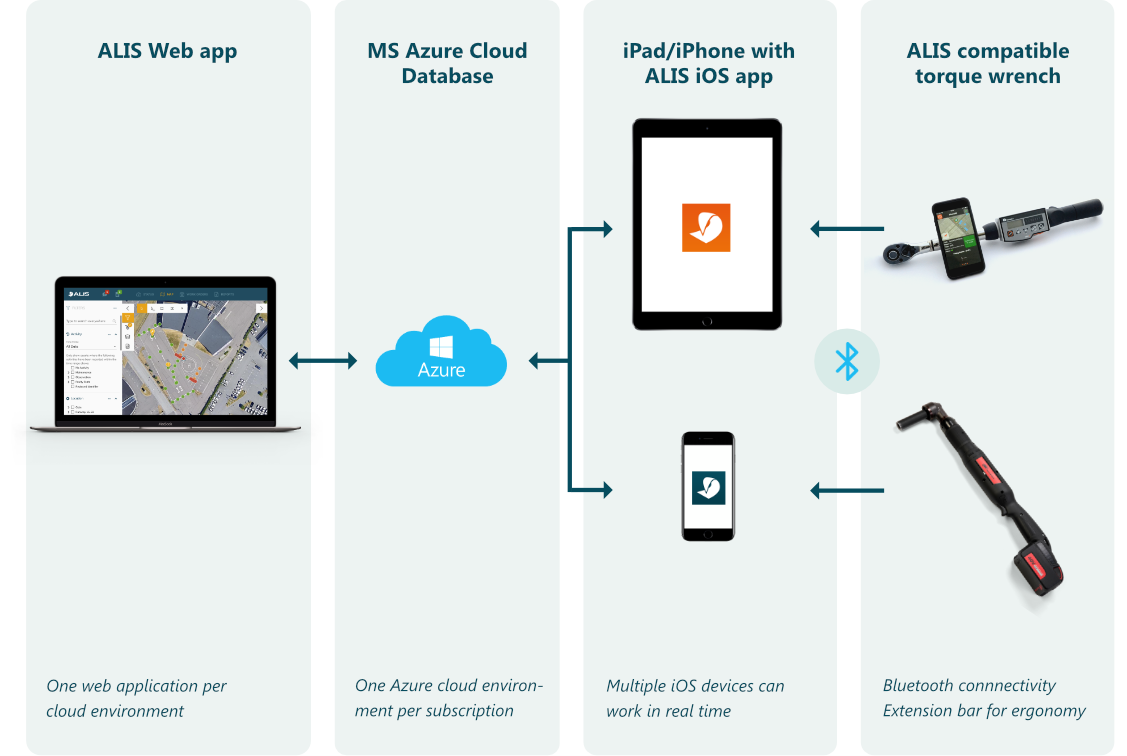

Using the mobile ALIS apps, technicians will be able to capture more accurate data in the field and create real proof points based on them. This add-on also allows you to create on-site observations with pictures, notes, and voice memos and to mark assets as faulty. You can interface an ALIS-compatible torque wrench with the app to receive and store actual torque values. ALIS on-site visualizes the airports’ on-site status in the web app even better and allows you to make data-driven decisions.

ALIS on-site seen from the sky!

ALIS compatible torque wrenches

IR QX Wrench

The innovative QX Series is a revolutionary step for your airfield, one that shows how a smarter tool can improve process control, operator comfort and data communication in a single package while increasing productivity, lowering costs and ensuring a high-quality installation of your airfield lighting.

Tohnichi Wrench

This ALIS compatible torque wrench is used for ergonomic torque inspections and fixations where the applied peak torque can be registered in ALIS. High brightness LED, which allows easy tracking of the tightening condition, robust and durable aluminum body. 10 different target torque values can be programmed and easily recalled by alphabetic registration. With CE mark. For international use including the EU region.

Bluetooth connectivity

All ALIS-compatible torque wrenches are equipped with a Bluetooth® low energy module for seamless integration of the wrench with the ALIS iOS Interface. The values registered by the torque wrench can therefore be used for the validation of maintenance tasks requiring torque registration.

Ergonomic extension bar

The included extension bar allows more ergonomic standup torquing which results in a lower level of effort and more accurate torque. Two versions are available, both rated for 100 Nm of torque that can be applied. Sockets can be for M10 bolts or for the US- standard 3/8″ – 16 UNC hex bolts. The sockets are glued to the extension poles to prevent FOD loss of sockets on the runway.

Use Cases

Work orders and ad-hoc maintenance

When assets are due for maintenance, a work order can be created in the ALIS Web application. These work orders list the assets and instructions for the task at hand. One or multiple technicians can fulfill the work order and they can even be handed over to other colleagues when it’s time to change shifts.

When no work orders are planned, any technician can register maintenance performed as ad-hoc: this allows for registration and keeping track of those things we can’t foresee on-site and where quick action is required.

Validation or torque tasks

Digital registration can happen by validating the tasks and marking them as “done”. The asset’s status will be updated in the cloud, with a time stamp and registration of user, workorder, etc.

You can also choose to create a torque value proof-point for the task. The performed task will then be validated when a valid torque value, from an ALIS compatible wrench, is received. As a bonus, you can register missing bolts directly on-site: that way you can later filter out these specific assets and create a workorder to go and fix them!

On-site observations

An airport is never a boring place and every day we can encounter new issues. In order to keep track of these incidents, you can create an on-site observation with a note or picture to inform the workorder manager about what is happening on-site, and to allow them to take the appropriate action.

Requirements

ALIS on-site works with Apple mobile devices (that can run the latest version of iOS).

You’ll need an iPad (preferably with SIM) with the ALIS TEAM app in order to collect the work orders and to register low volume maintenance tasks or observations.

When there’s a need to work on a larger volume of assets, you can pair up an iPhone with the ALIS PERSONAL app and enjoy the comfort of a smaller device that can perform AUTOMATIC ASSET SELECTION and identification. An unlimited amount of iPhones can be paired with the iPad, which collects the maintenance data from the iPhones.

You can also pair up an iPhone with the ALIS compatible wrench in order to get torque values in the system.

For more location precision, you can pair up the iPhone with our ALIS increased location identification and get up to 50 cm accuracy!

ALIS on-site requires the Satellite view add-on and asset location data in order to operate.

The hardware needed for ALIS on-site is not included in the subcription. You can purchase a validation set from ADB SAFEGATE but you may also use your own devices. (Configuration and support for devices not purchased with ADB SAFEGATE cannot be given)